RS-A6025 is designed with two universal holes for applications that require an RFID tag which can be screwed tightly on the metallic object.

Benefits

-

01

Professional Design Ability

- Design of the microwave ceramics

- Development of the Antenna

- Design of special label

-

02

Strict Quality Control System

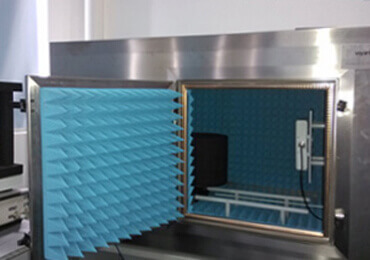

- Anechoic Chamber,Tag Formance,All kinds of analysis test equipment

- Professional environmental laboratory

- 10 large pressure machines,6 DEK printing machines,30 network analyzera,More reading and writing equipments

-

03

We can Support

- AL Bonding,Golden wire bonding

- UV Printing,Laser

- Ultrasonic Welding

- Reliability Test,Consistency Testing

|

Product |

RS-A6025 |

|

Size(L*W*H) |

60x25x3.4mm |

|

Protocol |

EPC C1G2(ISO 18000-6C) |

|

IC Type |

Impinj M4QT |

|

Application |

Metal containers and any metal items that can put the tags, Logistics, IT assets, Equipment, Tooling |

|

Avg.Read Range |

Fixed Reader:≥3m |

|

Alien Handheld Reader:≥1.5m |

|

|

Operating Temperature |

-25℃ ~ 55℃ |

|

Ambient Temperature |

-40℃ ~ 85℃ |

|

Frequency |

902~928(US), 866~868(EU), 920~925(CN) |

|

IP Rating |

IP63 |

|

Fixed Form |

Screw, Rivet, AB strong glue, Tie or 3M 300LSE tape(opt) |

TEST PERFORMANCE

-

Temperature Shock Test

Pass (from -40 degree to 150 degree, 6 hours per circle, 7 days total)

1 -

Solvent Test

95% Alcohol test pass, #92 Gasoline test pass

2 -

Drop Test

Pass (200 times from 1 m)

3 -

Opption

Silk printing, Laser printing , Pre-encoding, Customized data label, Surface painting (after painting, the IP rating can be IP65), Photo or graph painting (need to do surface painting firstly)

4 -

Remark

Can customize PCB tags for customers basing on the requirements of frequency, sharp, size, chips, read range, attachment method, and so on

5