RS-4631 high temperature resistance metal tag is designed and manufactured for use in harsh environment, its installation on the surface of metal material, its long-term resistance to high temperature of 200℃, long-term resitance to acid and alkaline environment, and can withstand ultrasonic cleaning.

This tag installation flexible, can use rivet installation, or screw installation.

The reliability of the tag can withstand: high temperature test, high and low temperature alternating test, acid base test, vibration test, ultrasonic washing test.

Specifications:

|

Protocol |

EPC Class Gen2; ISO18000-6C |

|

Working Frequency |

902~928MHz(US), 865~868MHz(EU)(Customize other specific frequencies) |

|

Chip |

Alien H3(customize same resist high temperature tags based on M4QT, Ucode8, Ucode7M, R6P) |

|

Chip Memory |

Alien H3: EPC 96bits, User memory 512bits |

|

Read & Write Performance |

R/W (Customer an rewrite the information) |

|

Data Srorage |

20 years |

|

Warranty |

1 year |

|

Main Material |

High temperature resistant injection material & ceramic material |

|

Weight |

21g/pcs |

|

Working Temperature |

-25 ~ 95℃ |

|

Storage Temperature |

-45 ~ 200℃ |

|

Peak Temperature |

230℃ @ 1 hour |

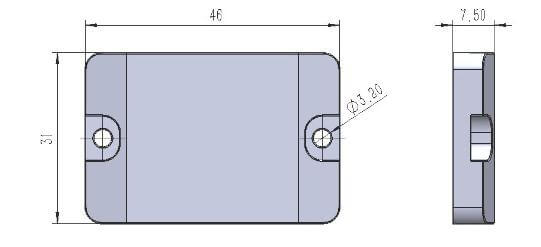

Product Size:

|

Dimension |

46×31×7.5mm |

|

Hole Diameter |

3.2mm |

|

Hole Center Spacing |

39.6mm |

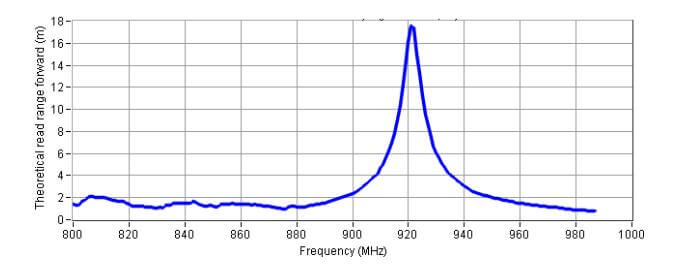

RF Performance:

|

Fixed Reader (on metal) |

Over 6m (4W EIRP,by Alien9900 fixed reader, maybe different by other reader) |

|

Hand Reader (on metal) |

Over 2.5m (Via Alien9011 hand reader at the outdoor space, maybe different by other reader) |

|

Polarization Mode |

Linear Polarization |

|

RF Performance Consistency Test |

100% passed by Finland Voyantic tester |

Reliabilith Testing:

|

High Temperature Testing |

200℃ @ 180 days |

|

Alcohol Testing |

95% Alcohol test pass |

|

Gasoline Testing |

#92 Gasoline test pass |

|

Temperature Shock Testing |

Pass (from -40℃ to 150℃, 7 times, 2 days total) |

|

RoHS |

Passed, Material passed SGS certification |

|

IP Tating |

IP68 |

|

Ultrasinic Cleaning Testing |

Passed |