What can we do?

-

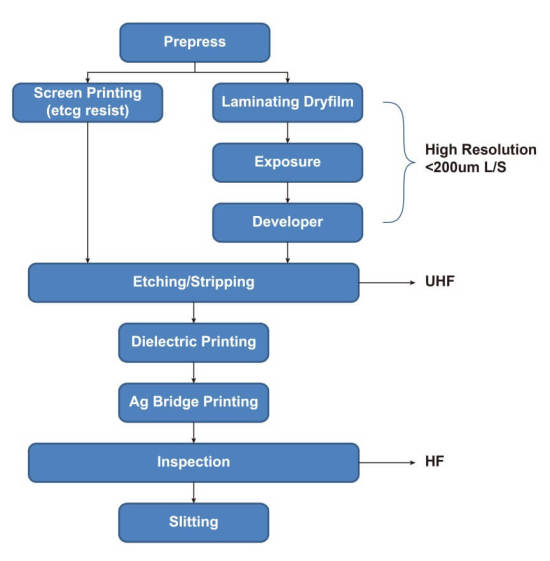

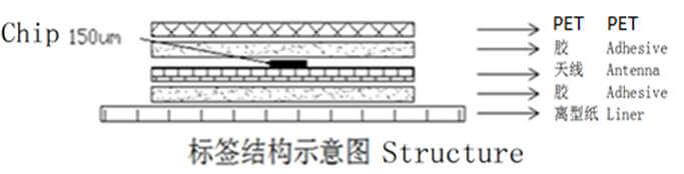

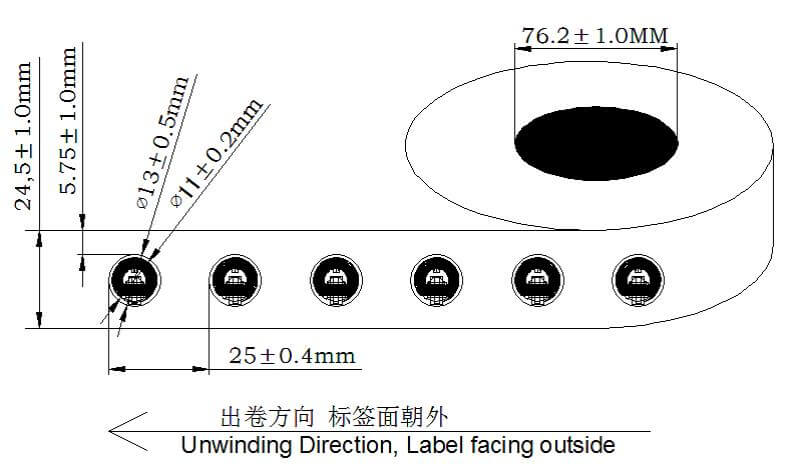

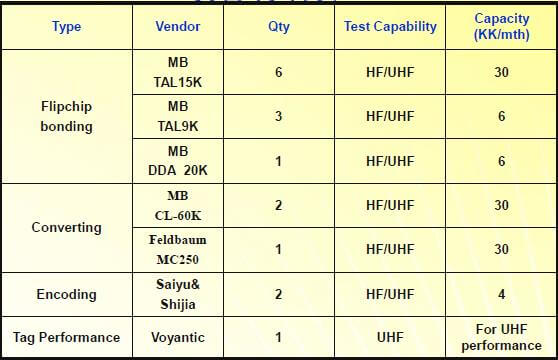

HF and UHF copper antenna custom design and production

1 -

Copper antenna inlay and tag custom make.

2 -

Single side Cu laminate, PET film, plus silver bridge for HF requirement, OSP optional, L/S= min. 75um, Roll to Roll production

3